Aragón, leader in pork production at the national level and pioneer in artificial intelligence in the sector

Aragón, leader in pork production at the national level and pioneer in artificial intelligence in the sector The community produces

Aragón, leader in pork production at the national level and pioneer in artificial intelligence in the sector The community produces

This article talks about the INSPECTRA LABEL CHECKER label inspection application, which has been updated to version 1.7

Automatic inspection of flow pack packaging using AI Flow pack packaging Until now, automatic inspection of quality defects in flow

Automatic caudophagy assessment system using artificial intelligence INNDEO participates in the CAUDOPIG R&D project with the company Le Porc Gourmet

This article discusses the consequences of mislabeling both in export packaging and in a packaged product in a supermarket.

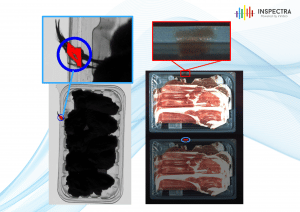

Detection of quality failures. Processed meat products Sausages, nuggets and other products such as hamburgers, are made with minced meat

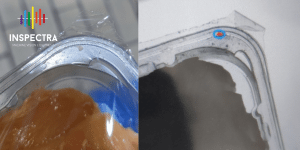

Machine vision inspection of packaging Heat-sealed packaging Heat-sealed packages are those in which the trays are thermoformed prior to the

OPTINVAS Project Artificial intelligence applied to quality and packaging processes What does the project consist of? OPTINVAS consists of the

INNDEO&INSPECTRA en Meat Attraction 2023 The INNDEO & INSPECTRA team was once again present at Meat Attraction 2023, the key

Most common labelling errors Food sector Product labelling is a key step in the product manufacturing process, especially in the

PACKAGING INSPECTION What is the most suitable vision technology for each type of packaging? When selecting the most suitable technology

INSPECTRA participates in Empack 2022 The future of the packaging sector The 14th edition of Empack Madrid took place last