PACKAGING INSPECTION

Quality failures in packaging

Hermetic packaging (MAP, EMAP, vacuum, skin, etc.) preserves the freshness of the product by means of a controlled atmosphere or the vacuum itself. To do this, it is essential to guarantee its correct thermosealing, otherwise the product will lose its qualities and will perish before its best before date, even causing food safety problems. This leads to serious quality problems, and is normally the cause of rejection of whole consignments of products already dispatched.

In order to guarantee the quality of the packaging, the surface of the film and the tray must be perfectly clean in the sealing area, as any type of contamination here will result in the loss of its airtightness, with the consequent degradation of the product.

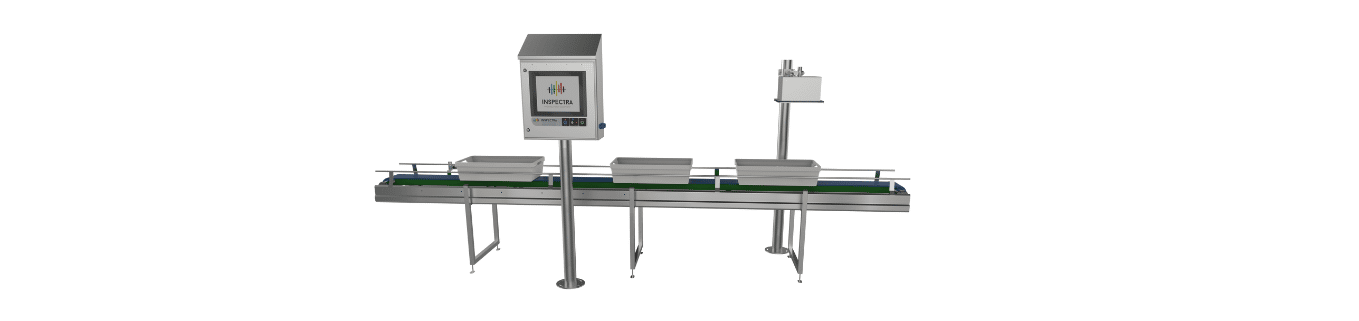

Packaging inspection by machine vision

Packaging inspection by Deep Learning

Deep Learning Processing Technology is an advanced data processing technique that can significantly improve the accuracy and efficiency of defect detection and quality inspection of packaging. It is an advanced method of data processing that mimics human learning through hierarchical or structured automatic algorithms. This system is able to learn by itself without the need for additional programming, through a previous training phase.

One of the most important applications of this technology is image classification, which enables product classification tasks or the detection of defects that cannot be identified by tone comparison using artificial vision techniques. Semantic segmentation is a deep learning technique that allows the trained defect classes to be located with pixel precision. This technique makes it possible to solve inspection tasks that previously could not be performed or could only be performed with significant programming effort.

At INNDEO&INSPECTRA we apply Deep Learning processing to the detection of defects in sealing film. The most common defects, such as wrinkles or roll defects, can be accurately identified and classified using this technology. This enables faster and more accurate detection of packaging defects.

Another application of Deep Learning processing technology in packaging inspection is the detection of foreign bodies and quality deviations of the packaged product. This technology can detect even the smallest foreign bodies in the packaged product, ensuring that the final product is safe and of high quality.

We also apply semantic segmentation technology in the detection of product positioning anomalies. This technique allows us to accurately identify the position of the product inside the pack and to detect any anomalies or deviations in product positioning.

Hyperspectral and monospectral package inspection

Quality control in the welding area is usually carried out using RGB artificial vision systems in the visible range.

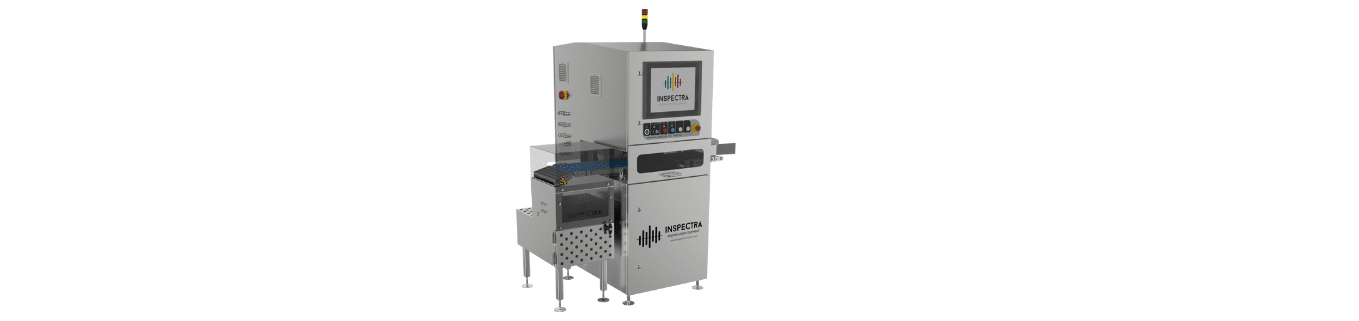

INNDEO&INSPECTRA incorporates this technology in its inspection equipment, applying high-resolution RGB vision systems with optimised detection algorithms, with excellent results.

However, when the contamination in the welding area is more complex (molten grease, interleaver invasion, transparent plastics, etc.), when the film inks are not uniform or when it is necessary to see through opaque inks, RGB vision technology is not sufficient for effective detection. As a solution to these problems, we incorporate hyperspectral vision technology and monospectral vision technology in our equipment, being able to detect these more complex defects, which until recently the technology on the market was not able to solve.

Hyperspectral imaging technology is an imaging technology that uses a wide range of wavelengths to capture images of an object or scene. This technology uses cameras that can capture images in hundreds or thousands of narrow spectral bands, making it possible to identify and analyse materials and components in an object or product with high accuracy.

Hyperspectral vision technology, developed and patented by INNDEO&INSPECTRA for packaging inspection applications, allows the analysis of the seal by detecting contamination by transparent elements (different chemical composition) and by seeing through opaque inks, something completely innovative in packaging inspection technologies.

Hyperspectral vision is also used to detect problems in the packaging process, such as the presence of air bubbles, lack of sealing or poor seal quality. Hyperspectral vision technology can identify and localise these problems with high accuracy, allowing for a quick and efficient correction of the packaging process.

This technology also makes it possible to characterise the chemical composition of the surface of the packaged product, allowing the presence of foreign bodies to be detected and the product to be classified according to the presence of chemical compounds (e.g. percentage of lean/fat, moisture, etc.).

Another application of hyperspectral vision technology in packaging inspection is fraud detection. The technology facilitates the detection of the presence of unwanted ingredients in packaged products, which improves the safety of the final product.

Monospectral vision is an imaging technology that uses a single wavelength of light, usually in the visible or near-infrared range, to capture images of an object or scene. Unlike RGB vision, which combines three different spectral bands to form a colour image, monospectral vision captures a single spectral band and produces a black and white image.

Monospectral vision technology is based on the principle that different materials absorb and reflect light differently at different wavelengths. By using a specific spectral band, it is possible to analyse how light interacts with materials and thus determine their composition and physical characteristics.

We also apply this technology to the detection of defects and anomalies in packaged products. For example, it can be used to detect the presence of foreign bodies in products or to identify defects in the packaging seal. It is also used to measure the quality of the packaged product, such as the level of ripeness of fruit or the amount of fat in meat.

Monospectral vision technology is especially useful in the detection of objects or substances that are not visible to the naked eye or that blend in with the surrounding material. For example, it can detect micro-cracks or fractures in packaging, which could cause leakage or contamination of the product.

These applications are tailor-made for each type of packaging and product, and it is essential to carry out an initial scoping phase with the customer in order to determine which technology or combination of technologies is the most suitable in each specific case.