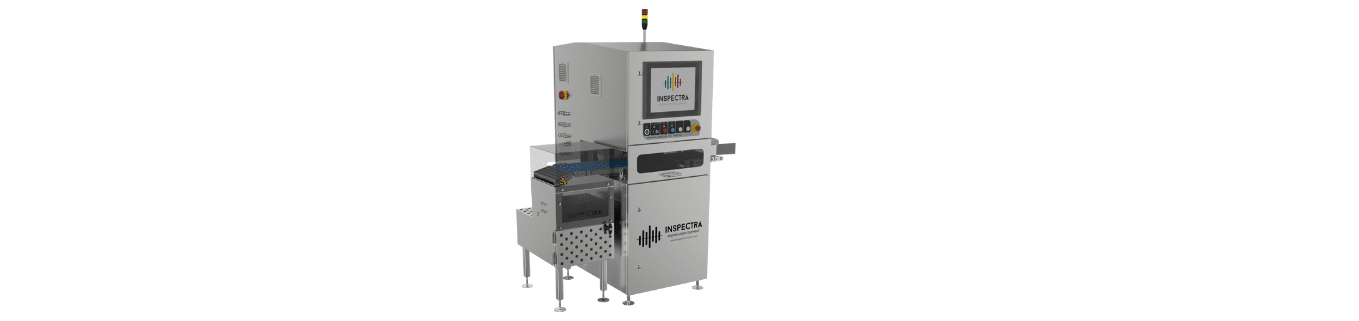

THERMOSEAL-LABEL INSPECTOR

Machine vision equipment for packaging inspection

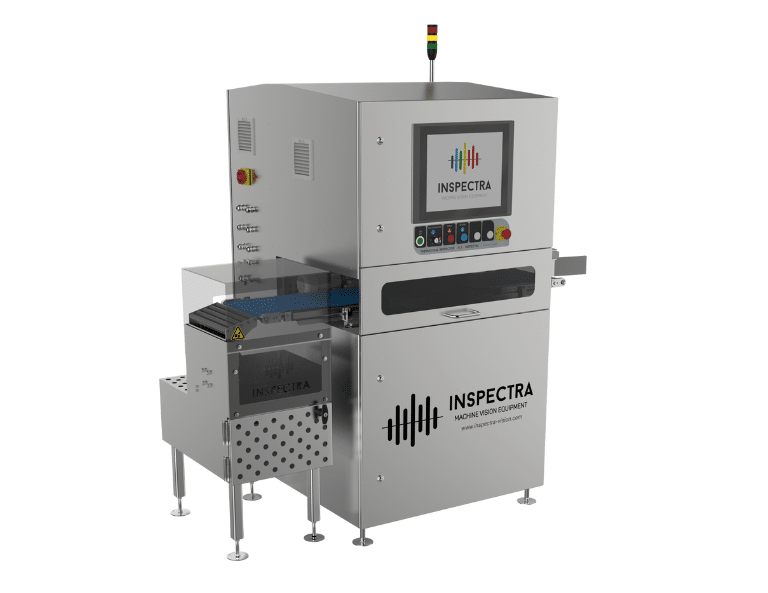

The Thermoseal Inspector and Label Inspector range of equipment analyses any type of packaged product in the food industry.

They are quality inspection devices designed to check labelling, the integrity of the heat seal area or other quality aspects of the packaging. Depending on their configuration, they are also capable of analysing product quality deviations inside the package or detecting the presence of foreign bodies.

Their high processing power allows them to offer the fastest inspection speeds on the market, both for the inspection of labelling and for heat-sealing or other quality defects. They incorporate the latest technology in artificial vision, adapted to the inspection needs of each customer according to their requirements. INSPECTRA machines can combine different vision technologies to achieve the best in-line inspection performance. They incorporate high speed technologies (INSPECTRA HSP®), artificial intelligence by Deep Learning, NIR/SWIR hyperspectral imaging and high performance RGB/Mono imaging with advanced inspection algorithms.

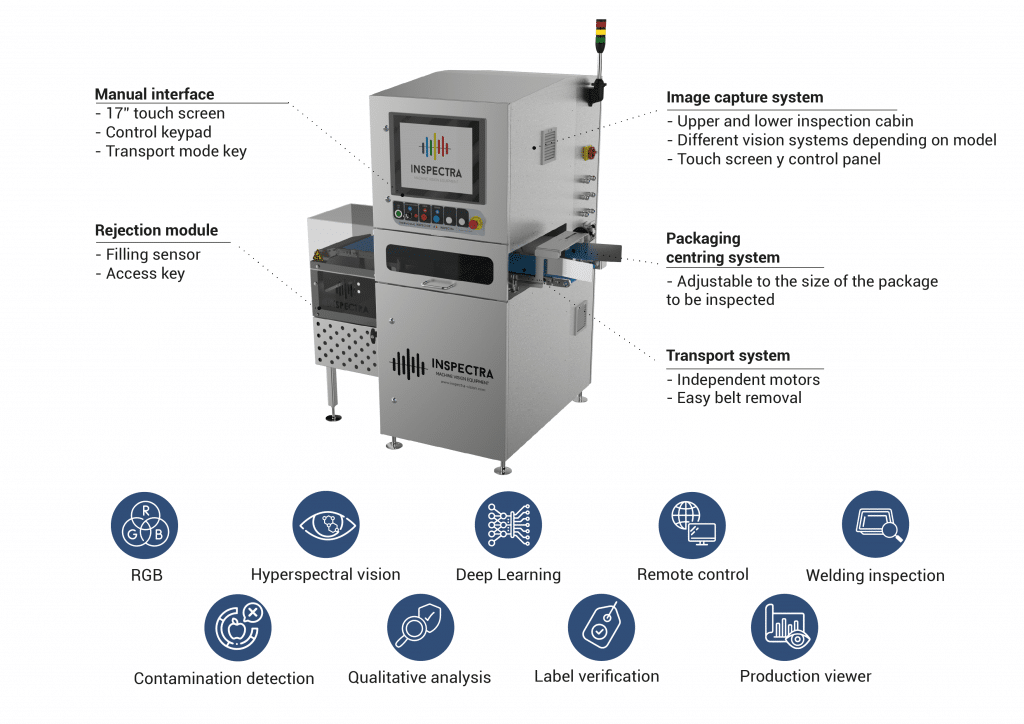

What are the advantages?

High reliability and performance in quality inspection

Inspection of the top and bottom side of the packages

Expandable and scalable to incorporate new inspection functions

Simple and quick configuration of labels and quality inspection programmes

The fastest inspection on the market

Options

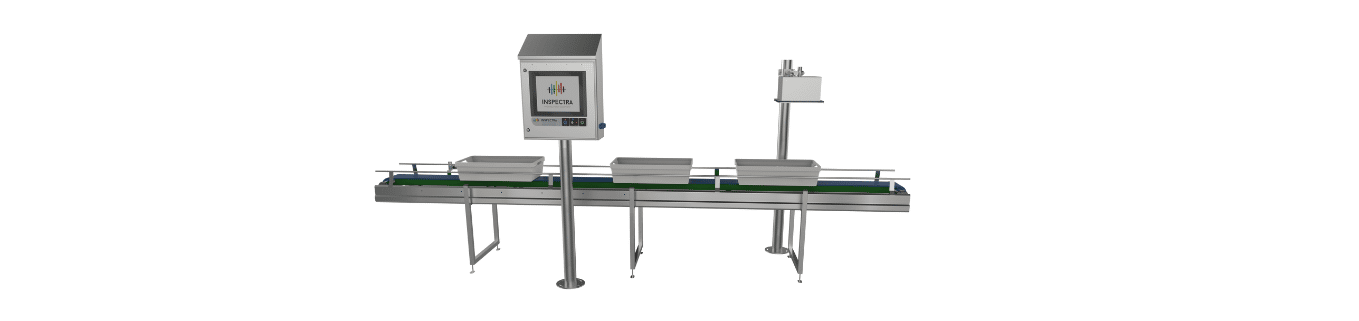

The Label Inspector incorporates the same frame and architecture as the Thermoseal Inspector Stantard model, and offers the functionality for advanced inspection of labelling and codes printed on the film, for both top and bottom side of the packages.

Thermoseal Inspector offers different options depending on the type of container and the defects to be detected. The Standard model, designed for simpler containers and defects, and the Advanced model for the inspection of more complex containers. In addition, both include the option of label inspection.

THERMOSEAL INSPECTOR STANDARD

This equipment option inspects packages inspection using RGB vision technology, with high performance in terms of speed and detection accuracy. It can include up to 3 cameras and has 2 inspection gaps.

THERMOSEAL INSPECTOR ADVANCED

This equipment option inspects packages using hyperspectral vision technology, identifying its chemical composition and assigning different shades of colour. It can include up to 5 cameras and has 3 inspection gaps.

Functionalities

- Detection of contamination or defects in the welding area of the heat seal

Quality inspection of the packaged product: contamination, quality parameters, incorrectly positioned product, etc.

Reading of texts and bar codes on the package

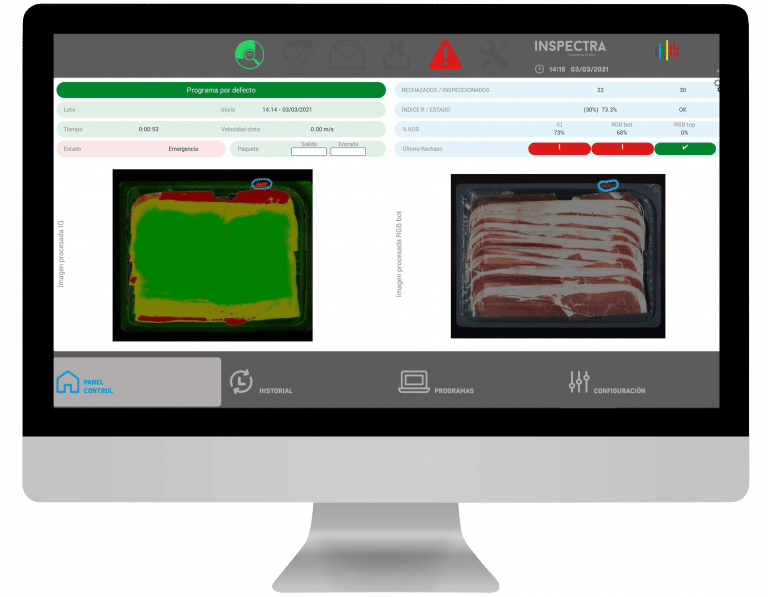

- Generation of quality indicators for inspected production

Production traceability, through images and data

Connection of the equipment in remote for visualization of data in real time

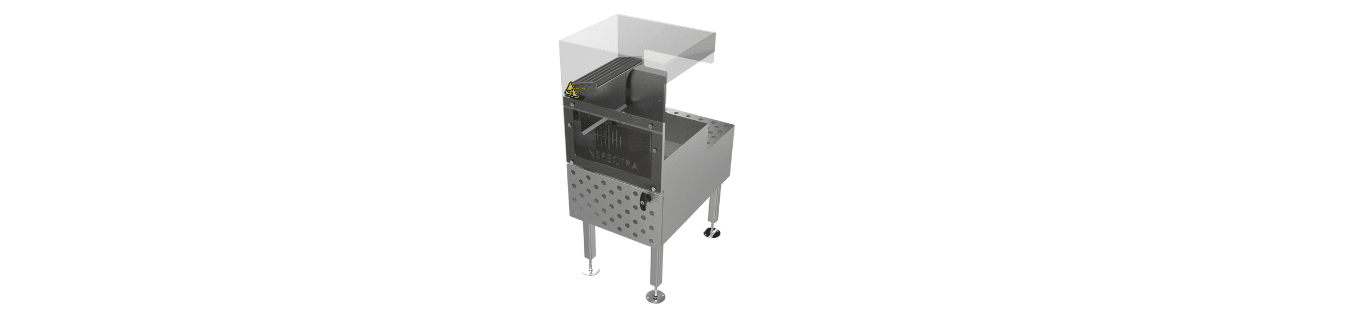

Easy connection with rejection modules of different technologies

Simple and ergonomic interface, with the possibility of adapting to customer needs

Specifications

THERMOSEAL INSPECTOR

Depending on the inspection requirements of the containers to be analysed, the Thermoseal Inspector equipment has image processing systems with hyperspectral technology in the SWIR and NIR ranges. This represents a technological and performance leap compared to conventional inspection systems.

Hyperspectral technology makes it possible to segment the chemical footprint of the components it inspects, easily differentiating defects or contamination that at first sight could be mistaken for having similar colour shades. In the Thermoseal Inspector equipment, it is applied to give greater power to the inspection of the heat seal, and for the detection of contamination or quality deviations in the packaged product.

The equipment is capable of inspecting the top and bottom of these packages, obtaining and processing images of both the product and the package itself, even in the case that these films are printed with inks that are opaque to visible light.

Its main applications are aimed at:

- Detection of (complex) contamination in the heat-sealing area: melted fat residues, interleaver invasion, invasion by sealing film fragments, etc.

- Presence of foreign bodies and deviations in the quality of the packaged product

- Detection of incorrectly positioned product in containers with opaque inks

Depending on the inspection requirements of the containers to be analysed, the Thermoseal Inspector equipment has high-resolution RGB artificial vision systems, within the visible spectrum.

INSPECTRA’s processing algorithms for RGB vision technology have been refined and are the result of years of development, achieving high performance in terms of speed and detection precision, which allows for high efficiency in the detection of contamination and quality deviations.

Its main applications are aimed at:

- Contamination detection (simple) in the thermosealing area

- Presence of foreign bodies and deviations in the quality of the packaged product

- Detection of incorrectly positioned product in containers with transparent inks

- Top and bottom print reading on packaging: text and barcodes

- Detection of the presence or absence of labels

The equipment can include Deep Learning systems in all its modalities (Standard and Advanced). This technology consists of an automatic hierarchical or structured algorithm that emulates human learning to obtain certain knowledge. The system itself is capable of learning by itself through a previous “training” phase, without the need for additional programming.

Image classification based on deep learning enables product or defect classification tasks to be carried out using machine vision techniques.

By means of semantic segmentation, trained defect classes can be located with pixel precision. This allows inspection tasks to be solved, which previously could not be performed, or only with significant programming effort.

Its main applications are aimed at:

- Detection of contamination in the heat-sealing area.

- Detection of anomalies and defects in the heat-sealing area: wrinkles, roll defects…

- Presence of foreign bodies and deviations in the quality of the packaged product.

- Detection of incorrectly positioned product

Do you need more information?

If you want more information about the Thermoseal Inspector equipment, fill in your details and receive the catalogue by email.