LEADING MANUFACTURER OF INDUSTRIAL MACHINE VISION EQUIPMENT FOR AUTOMATIC INSPECTION

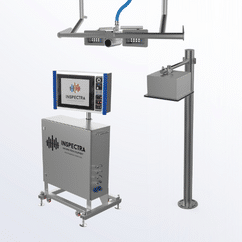

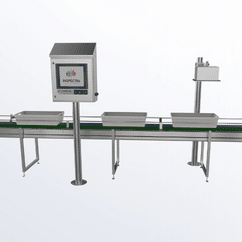

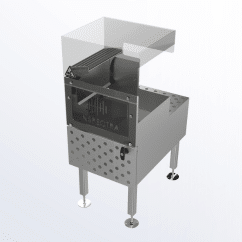

OUR EQUIPMENT

Discover our catalogue with all the machine vision solutions and technologies for the automation of quality inspection:

Automatic vision and artificial intelligence inspection solutions

We are manufacturers of industrial machine vision equipment for automation of quality inspection processes, with the latest vision and artificial intelligence technologies. Our equipment are integrated into production lines, automating the removal of products that do not meet quality criteria, providing the following benefits:

- Reduction of personnel costs: Our equipment automate manual inspection tasks, reducing personnel costs (selection, hiring, training, management, rotation, absenteeism).

- Reduction of costs due to complaints: We reduce the complaints of your clients: financial penalties, destruction of items, product returns, tensions with the client, unforeseen events in production, etc.

- We contribute to the improvement of your OEE

- We digitize 100% of your production, offering you data for continuous improvement of your processes and your suppliers.

- Traceability and registration of all defects in both packaging and fresh product.

- Real-time alarms in the event of quality deviations on the line.

- The high inspection speed of the equipment makes it possible to increase the production speed of your lines.

- Greater reliability in your quality inspection

- Our inspection is objective, parameterizable and constant.

- We detect quality defects that cannot be detected in a manual inspection: by size, speed and transparency, visual spectrum.

- The best inspection performances on the market, with patented INSPECTRA technology.

- We ensure your brand image before the most demanding clients

- Fewer incidents of quality of the products that can reach the consumer, preserving your brand image.

- Demonstrating to its customers its commitment to quality by incorporating the most advanced inspection technologies on the market in the production process.

OUR TECHNOLOGIES

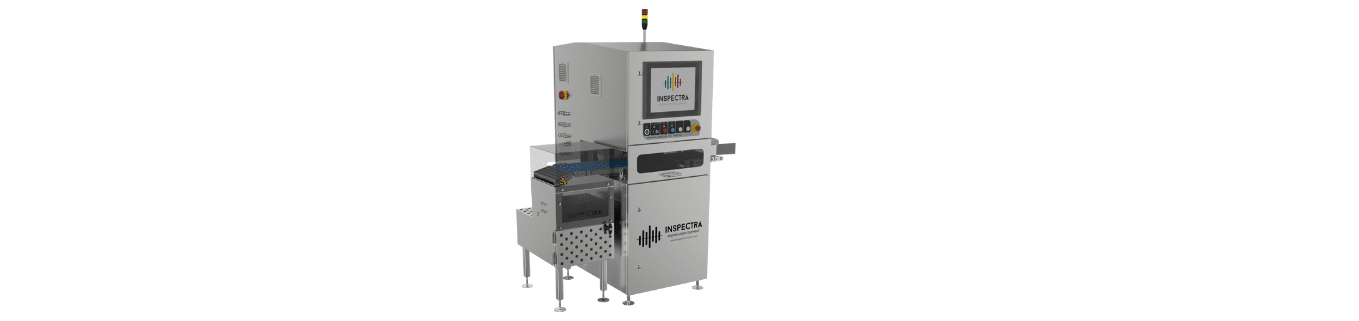

HSP®:High-speed vision

In some of our inspection equipment such as the SLICE INSPECTOR we integrate high-speed matrix cameras, allowing us to monitor processes that happen at very high speed, such as slicing, in which images are captured by tracking the position of the blade on the block, determining the frames in which there is no occlusion of this on the product and the slice can be captured in an ideal way, to process it through our vision and artificial intelligence programs on the slice

In other inspection equipment such as THERMOSEAL INSPECTOR we integrate high-speed linear cameras that allow inspection at a speed of 2 containers per second, capturing images with different high-resolution cameras, making the decision to accept or reject the container in a few thousand seconds.

All this is possible thanks to our patented HSP® technology, which makes use of the most advanced capture technology, and through our ISS image processing software optimized to run on powerful computing systems, without latencies and with parallelization of all images. processing loads between the different threads of the processor and the GPUs.

This technology allows decision-making in real time and in line with production processes, allowing the lines to operate at their maximum production speed.

EASY AI®: Vision with Artificial Intelligence

We apply Deep Learning technology in our equipment, which constitutes one of the fundamental bases of Artificial Intelligence. This technology is characterized by processing information through different convolutional neural networks trained tailored to each process.

Our Easy AI® technology solves complex classifications impossible until now for artificial vision algorithms, such as:

- Product classification

- Defect segmentation

- Product anomalies

- Count

- Reading distorted or jumbled characters

Deep Learning technology allows the system to be able to learn by itself, without the need for additional programming, through a previous training phase based on image labeling, allowing automated decision-making in real time. INSPECTRA’s artificial intelligence equipment has constant operation, which does not depend on the operator, performing the inspection automatically, more reliably and faster than human inspection

CHP®: Hyperspectral and chemical imaging

Hyperspectral vision technology allows products to be characterized using online spectroscopy techniques in the NIR and SWIR spectrum, while monospectral vision technology uses a single wavelength of light in the visible or near-infrared range.

Our CHP® technology performs non-destructive analysis of products by generating chemical images in real time. A chemical image consists of a representation of a hypercube in a 2D image, in which each spectral signature of a pixel is assigned a color hue. Our teams compose several chemical image models simultaneously and process them with our advanced vision processing technology and artificial intelligence with patented technology, allowing us to analyze the presence of foreign bodies online invisible to conventional vision systems and classify them. products based on quality criteria.

High performance vision in the visible range

Our advanced image processing algorithms allow us to push inspection performance to the limit using inspection technology in the visible RGB/Monochrome range. Their integration in our inspection equipment allows us to obtain very tight costs and high performance, efficiently solving a large part of the inspection needs of food production lines.

OUR CUSTOMERS