Chemical inspection of food

MEAT

Hyperspectral vision in meats

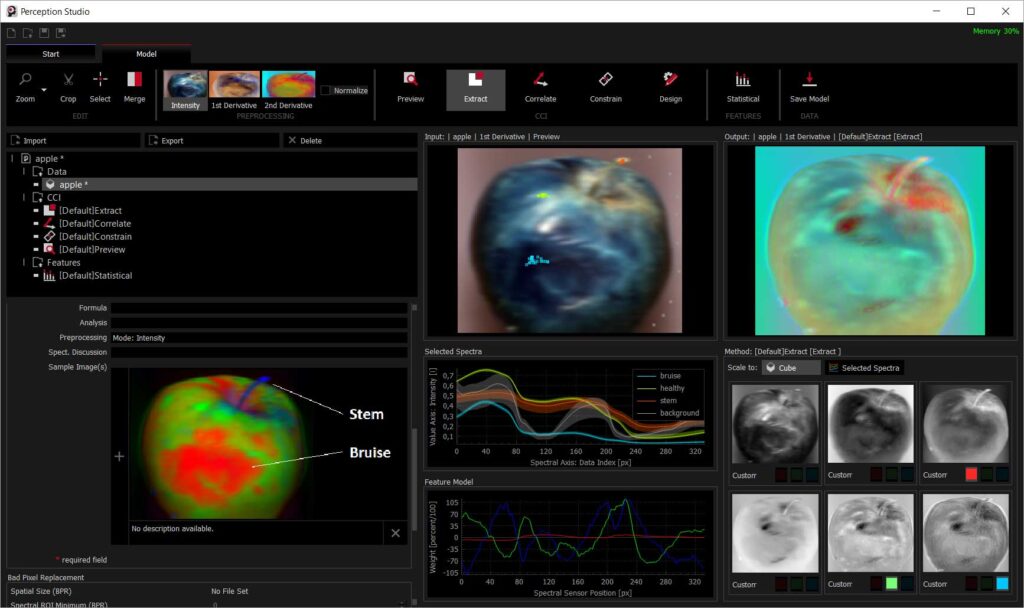

Hyperspectral cameras can reveal much more than conventional cameras or manual spectrometers.

Integrating hyperspectral vision equipment into quality control and classification processes improves capacity in product inspection and process analysis.

This equipment, combined with the chemical image composition software developed by INSPECTRA, allows automatic quality control tasks to be carried out on 100% of the production in line with the process.

Laboratory testing

Do not hesitate to consult with INSPECTRA the possibility to detect any quality defects presented by your products. We will be happy to test in our laboratory the possibility of detection using hyperspectral vision technology.

Our systems integrate different vision equipment allowing to automate the following inspection and classification tasks:

- Detection of surface contamination by foreign bodies (metal, plastic, bone, wood, parasites…).

- Classification according to quality parameters: tissue composition (lean and fat) or water percentage, among others.

- Detection of cutting defects (presence of viscera, bone chips, hair…)

FISH

Hyperspectral vision in fish

In the production of fish, it is important to know the date of capture to know which product has to go to market earlier, thus guaranteeing its freshness.

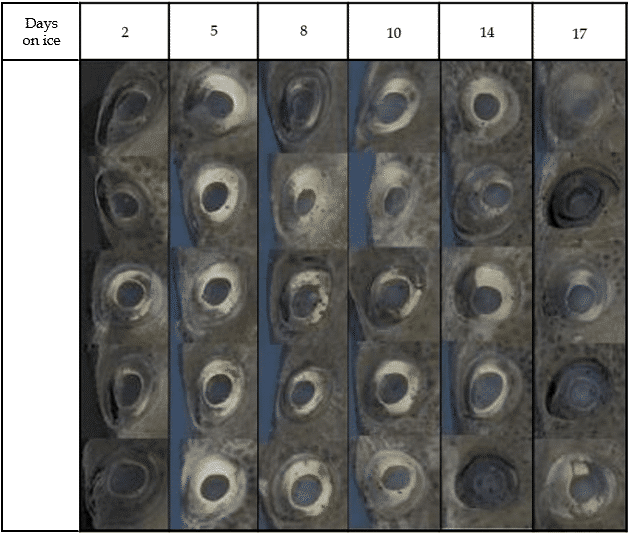

The variation in natural pigmentation in fish according to its date of capture and method of conservation is considerable. The main one is seen in the colour of the eyes, varying the luminosity from black to translucent white during the initial period of 2 to 8 days. The eyes colour changes with the days during its conservation in the ice.

The main colour change in the fillets occurs during storage, increasing the yellowing. This change can be detected by analysing the colour in the frequency spectrum of the shades from blue to yellow. Gill filaments also show a characteristic change from bright red to pale yellow over time.

Currently, to determine the freshness of the fish is only available with information from fishing boats, which is not always accurate and can be fraudulent.

Through the analysis of hyperspectral images, we obtain information quickly, safely and not destructively for the evaluation of freshness, analyzing different parameters of the fish, which allows us to discriminate between varieties of the same and estimate the date of capture.

The great potential of colour analysis by hyperspectral imaging to evaluate the freshness of fish at its earliest age (up to about 10 days), solves a problem for producers, since it is not easy to evaluate the freshness quality of the fish by analytical means.

FRUITS AND VEGETABLES

Hyperspectral vision in fruits and vegetables

Get mature, better-quality products with an optimized shelf life and reduce waste and rejection of quality product.

Integrate hyperspectral cameras into your quality control and classification processes to enhance your ability in product inspection and process analysis. Non-invasive real-time inspection replaces time-consuming visual inspections and laboratory tests. Our equipments allow online inspection of 100% of the product flow.

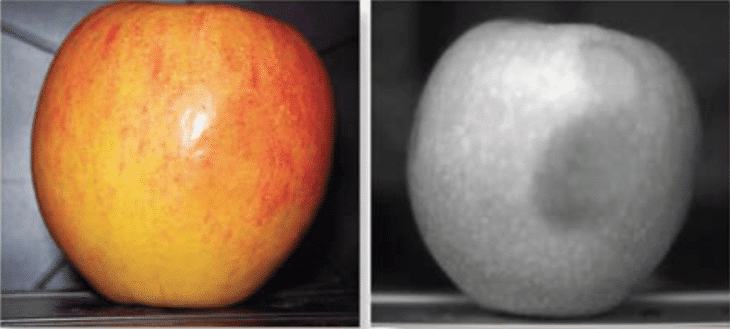

Our equipment allows to detect spots and bruises under the skin, to know the maturity and the chemical quality regardless of the colour and size of the fruit. It also allows detection and removal of foreign materials such as plastic, wood, paper, metal or insects.

For example, predicting the quality of high commercial value fruits such as avocado is difficult due to its non-apparent visual change. However, with hyperspectral vision, changes that are not visible to the eye can be detected and predicted. Changes in fruit quality have a specific spectral signature that can be detected with our equipment.

Other applications in fruits and vegetables can be:

- Early detection of damage from shocks, frost or cracks

- Maturity inspection

- Starch and sugar inspection

- Sugar content prediction and impurity detection

WINES

Hyperspectral vision in wines

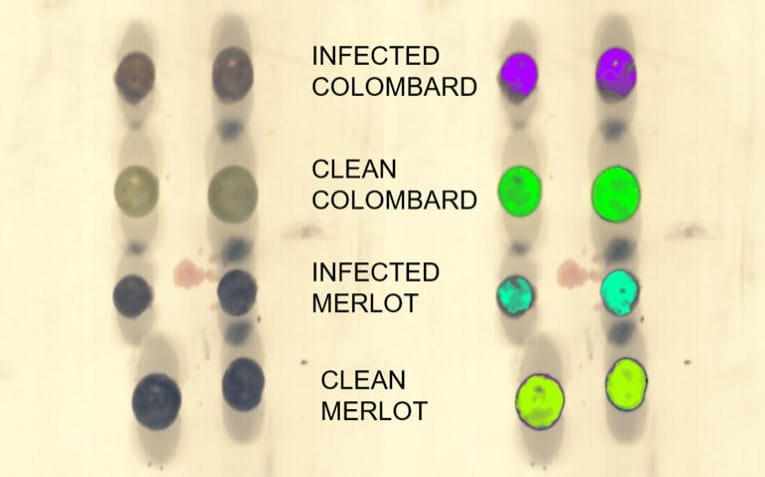

In wine production it is important to know the phenolic composition of each type of grape at each stage of the harvest to determine its antioxidant potential and possible industrial applications. In addition, it is necessary to do so quickly and accurately to speed up decision making and avoid product waste.

At present, physical-chemical analyses are carried out to determine the phenolic composition of the by-products of winemaking, which are slow and costly.

By analyzing hyperspectral images in near infrared (900 to 1700 nm) we obtain information quickly, safely and non-destructively for the evaluation of chemical composition. This allows us to discriminate between varieties, estimate the date of sampling and predict the flavanol content of the grape seeds.

Hyperspectral techniques are presented as an alternative to conventional chemical analysis since they allow us to estimate the content of phenolic compounds in the by-products without the need for a tedious sample treatment procedure or the use of solvents.