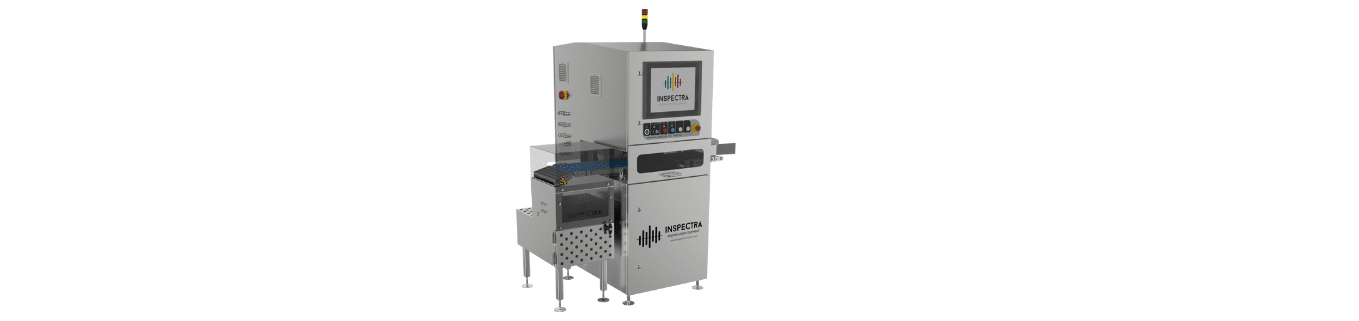

Slice Inspector

Machine vision equipment for inspection of sliced products

Vision module

- High-speed camera

- LED lighting system

- Suitable for different slicer models

Monitoring and control module

- 17’’ touch screen

- Control panel

- Deactivation key rejection

INSPECTRA Slice Inspector is a sliced products inspection device. It is powered by the most advanced technology in computer vision and artificial intelligence. As an industrial equipment designed for the food industry, it is prepared to ensure a stable and reliable inspection in the production lines.

This equipment incorporates INSPECTRA’s high speed processing technology HSP® and artificial intelligence Easy AI®. All these enable to boost the performance inspection rates. It is available in different configurations depending on the specific appliance.

INSPECTRA Slice Inspector analyses quality and foreign bodies of the sliced product. The inspection is carried out on each slice, thus analysing 100% of the production.

Types of inspection

Foreign bodies

Qualitative analysis

Others benefits

Production visualiser

IoT connectivity

Remote control

Equipment suitable for any sliced product

Functionalities

The equipment enables real-time inspection of a wide variety of sliced products. It also enables the most critical defects to be rejected and all programmed defects to be recorded, in order to analyse incidents and optimise production processes upstream of the equipment.

- Excess fat.

- Oxidation or yellowing.

- Mould.

- Blood.

- Product degradation and other specific quality defects.

- Plastics.

- Paper, navets.

- Other visible.

Features

Slice-by-slice inspection

100% inspection of each slice, detecting defects after slicing and before grouping.

Stability and robustness

The system is designed to operate under the harsh conditions of food production lines. Its internal design ensures maximum stability and robustness in machine vision inspection.

Selective rejection

The system is equipped to send a rejection signal upon detecting a quality anomaly. It features the ability to classify defects that require rejection from those that only need traceability, enabling selective rejection.

Adaptability to different slicers

The system can be integrated with the main commercial slicer models available on the market.

Patented high-speed vision technology

Patented high-speed vision technology that enables ultra-fast image processing, designed to keep up with slicing line processing speeds.

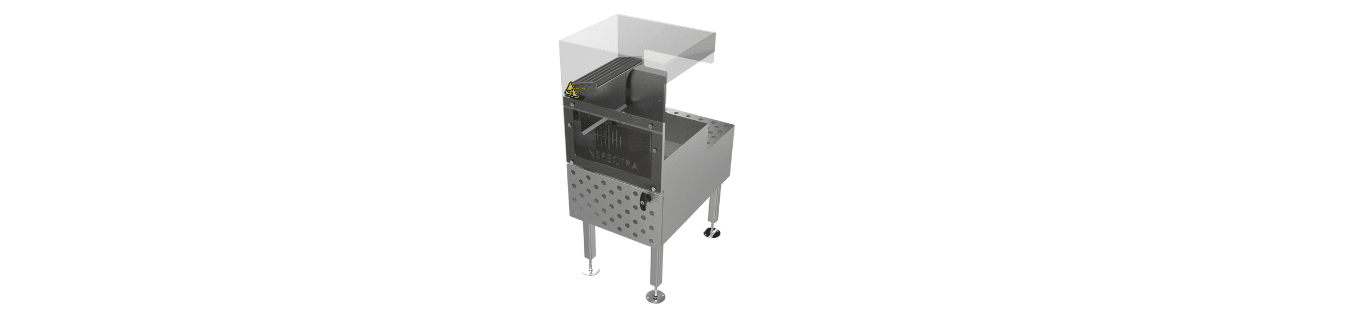

Adaptable control module

The control module can be adapted based on location and available space on the production line, as well as the ergonomics of the workstation.

Vision technologies

High-speed

vision and

performance

INSPECTRA HSP®, our high-speed technology allows us to offer the fastest in-line inspection speeds on the market do. Our extensive experience in developing innovative inspection equipment for the most demanding production processes in the food industry has enabled us to develop and optimise the most advanced processing hardware and software architectures. We include parallelisation technology with an efficient distribution of processing threads with state-of-the-art hardware.

Artificial

intelligence

Our equipment can optionally incorporate artificial intelligence technology INSPECTRA Easy AI® by Deep Learning for advanced inspections. By means of a previous training phase, the processing system is able to automatically learn the type of defects contemplated, offering great power and inspection performance.

Vision

RGB

Our inspection systems incorporate high-performance machine vision technology within the visible RGB spectrum. Thanks to our advanced image processing techniques, we apply the most suitable technology for each sliced product inspection application.

Do you need more information?

If you want more information about the Slice Inspector equipment, fill in your details and receive the catalogue by email.