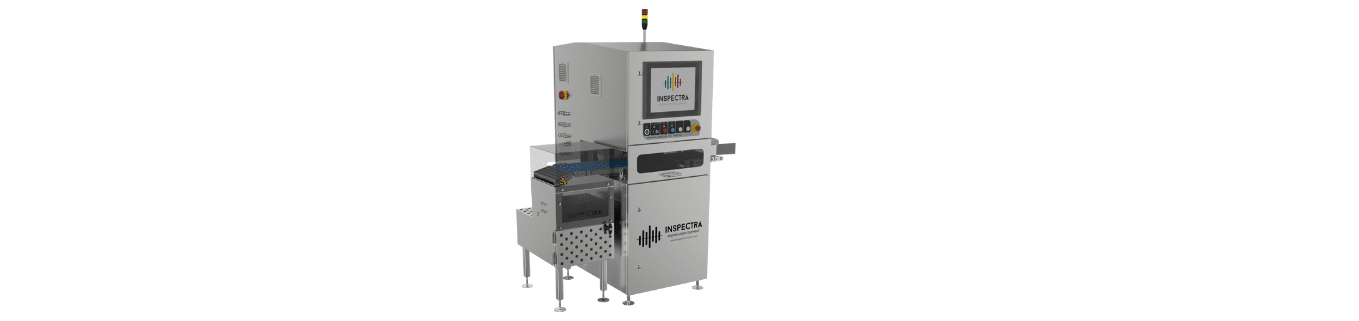

CARCASS CHECKER

Automatic machine vision carcass inspection equipment with artificial intelligence

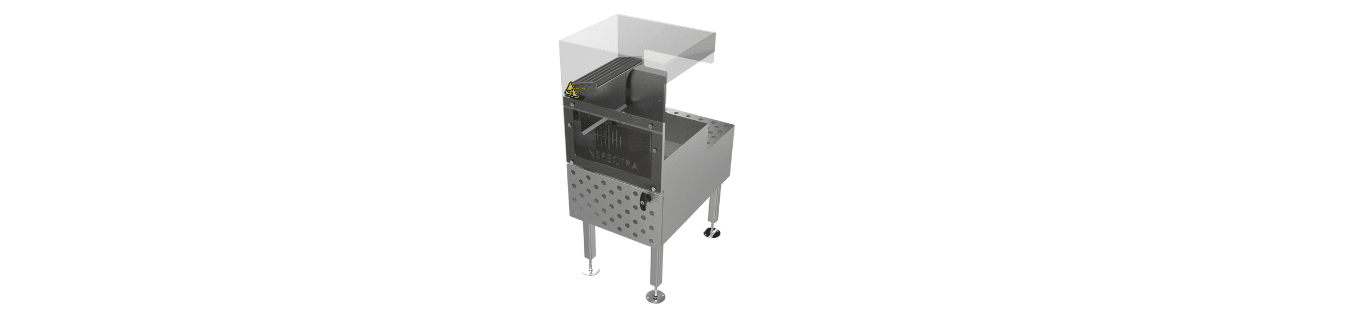

Vision module(s)

- Different configurations

- Adaptable mechanical supports

Control module

- Different configurations

- Control panel

INSPECTRA Carcass Checker is a carcass full-inspection device for slaughterhouses. It is powered by the most advanced technology

in computer vision and artificial intelligence. As an industrial equipment designed for the food industry, it is prepared to ensure a stable and reliable inspection in the production lines.

This equipment incorporates INSPECTRA’s high speed processing technology HSP® and artificial intelligence Easy AI®, which enables to boost the performance inspection rates. It is available in different configurations depending on the specific appliance.

INSPECTRA Carcass Checker analyses different areas of the carcasses and red organs in slaughterhouses. It is available in different configurations depending on the specific appliance.

Types of inspection

Foreign bodies

Animal welfare

Qualitative analysis

Classification

Others benefits

IoT connectivity

Remote control

Production visualiser

Specific inspection configurations

Functionalities

The equipment is installed on the customer’s production line, on both sides of the carcass production line.

Once a defect has been detected, the equipment sends a signal to divert the carcass either to the reprocessing loop or to another line.

This equipment can have different configurations with up to 8 vision modules, allowing for the installation of 2/4/6 modules on both sides of the conveyor chain, depending on the specific inspection appliance.

- More efficiently than operators.

- Caudophagy.

- Bile residues.

- Pus.

- Plastics.

- Cutting faults.

- A record of images from each carcass and of any defects detected is stored.

- Prepared to get traceability of carcasses using RFID tags from the slaughterhouse.

Vision technologies

High-speed vision performance

Our high-speed INSPECTRA HSP®, technology enables us to offer the fastest in- line inspection speeds on the market. Our extensive experience in the development of innovative inspection equipment for the most demanding production processes in the food industry has enabled us to develop and optimise the most advanced processing hardware and software architectures. We include parallelisation technology with an efficient distribution of processing threads with state-of-the-art hardware.

The high speeds and performance of our equipment allow us to process a huge amount of data and act in very short times with the rejection systems.

Artificial

intelligence

Our equipment can optionally incorporate artificial intelligence technology by Deep Learning for advanced inspections. We have adapted the technology and called INSPECTRA Easy AI® Through a preliminary training phase, the processing system is able to automatically learn the type of defect being inspected, offering high inspection power and throughput.

We have accumulated extensive experience and case studies of process information in the food industry, which allows us to have the best performance in neural networks.

Vision RGB

In our inspection equipment we incorporate high performance machine vision systems in the visible RGB range. Our advanced image processing techniques allow us to apply the best technology for your channel inspection application.

Combination

of technologies

INSPECTRA machines can combine several vision technologies simultaneously, when required. This allows for increased throughput and inspection functionalities depending on the type of packaging and specific product defects to be inspected. Our extensive experience in packaging inspection allow us to select the best combination of technologies for your specific application.

In addition, the devices are scalable and flexible and can be adapted to new inspection requirements through special adaptations.

Do you need more information?

If you would like more information about Carcass Checker equipment, please fill in your details and we will contact you to send you the technical catalogue.