💡Did you know that in-line inspection of this type of packaging is one of the most difficult to perform?

✔ They are usually double packs, very small, deep and sometimes irregularly shaped.

✔ Produced on high speed lines at more than 2 packs per second

✔ Sealing problems due to grease entrapment are very difficult to detect ✔ Different formats can pass through the same line: double and single.

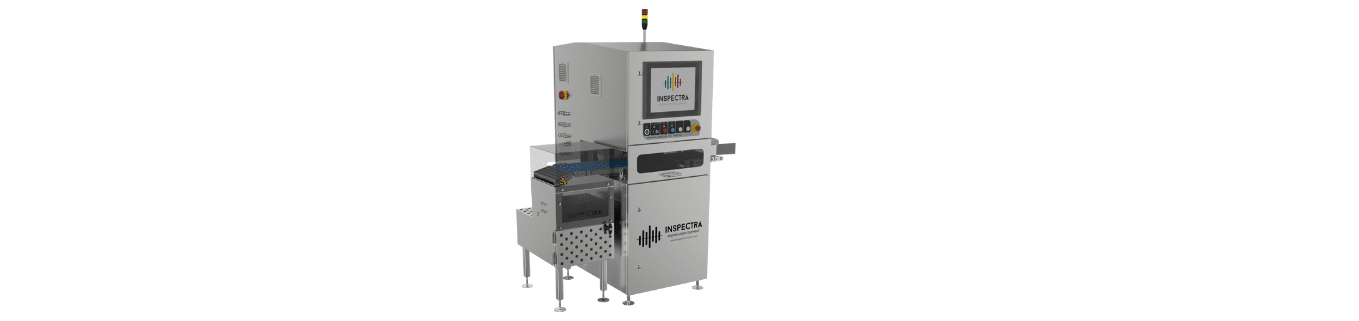

Our THERMOSEAL INSPECTOR ADVANCED is the only one on the market that offers the combination of the most advanced machine vision technologies to detect the leakage of protective atmosphere and ensure that the packs reach the supermarket shelves in the best condition, a technology patented by INNDEO🥇.

📌What does the THERMOSEAL INSPECTOR ADVANCED do?

✅ Monitors the production process using different cameras to perform complete quality control of the packs: sealing, labelling (top and bottom) and anomalies visible in any of the images.

✅ Applies our technologies: HSP® (high speed), CHP® (chemical imaging) and INSPECTRA Easy AI® (artificial intelligence) to monitor 100% of production online

✅ Rejects defective packs with high accuracy

✅ Extracts data to improve production process

✅ Eliminates manual inspection by operators, enabling full end-of-line automation

Do you want to know more?