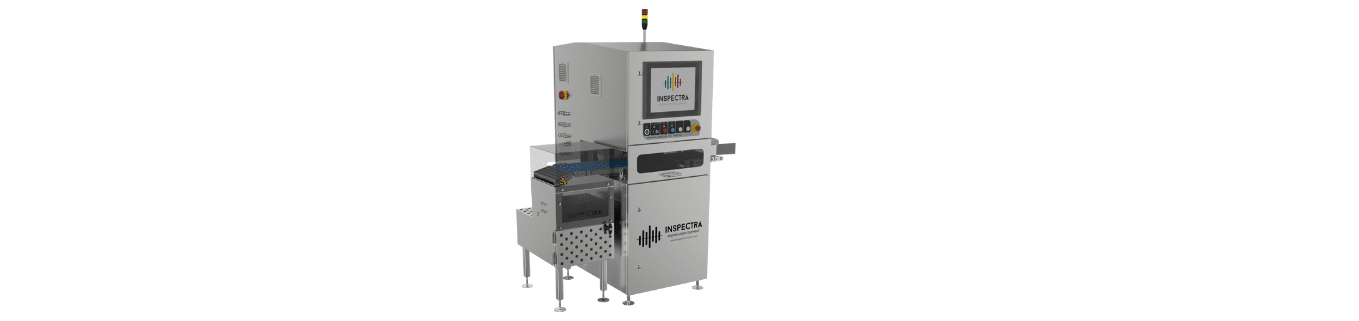

AI-SORTER

Advanced inspection equipment using vision and artificial intelligence

Control module

- Different configurations

-Centralised architecture

Vision module(s)

- Different configurations

- Adaptable mechanical supports

Code reading system (optional)

- RFID Antenna

- Code reader

INSPECTRA AI-Sorter is a multifunctional inspection device, adaptable and scalable for different applications, with simultaneous inspections at separate points through a centralised control architecture. It is powered by the most advanced technology in computer vision and artificial intelligence. As an industrial equipment designed for the food industry, it is prepared to ensure a stable and reliable inspection in the production lines.

This equipment incorporates INSPECTRA’s high speed processing technology HSP® and artificial intelligence Easy AI®, which enables to boost the performance inspection rates. It is available in different configurations depending on the specific appliance.

Types of inspection

Foreign bodies

Classification

Qualitative analysis

Top inspection packaging

Others benefits

IoT connectivity

Remote control

Production visualiser

Specific inspection configurations

Models and options

The equipment allows the complete visualisation of production histories according to the configured inspection functionalities.

It also allows for the easy introduction of new product categories without reprogramming algorithms, thanks to the built-in labelling and training tool.

- Multiple inspection points controlled under a single control module (centralised architecture).

- Different control module models depending on final equipment design.

- Possibility of control module in production area or in separate electrical room.

- Possibility of independent touchscreen display at each inspection point.

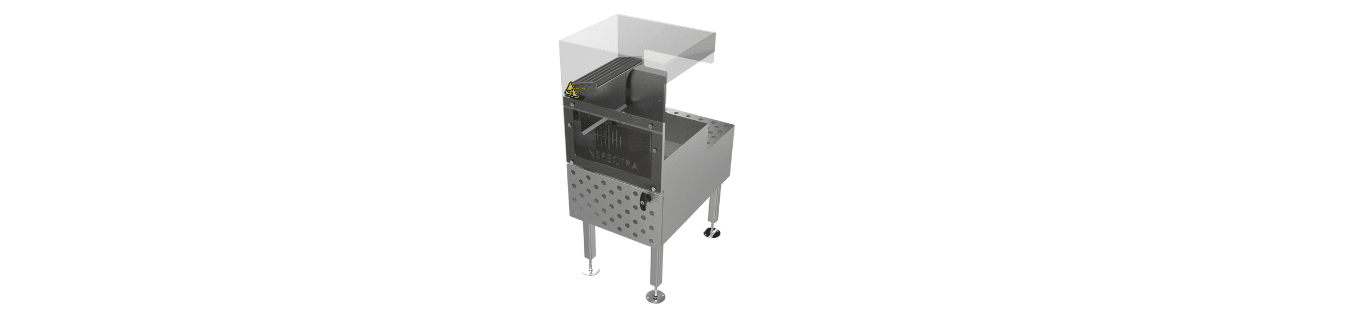

- Folding mounting systems for vision modules (to facilitate maintenance and cleaning operations).

- Adaptable according to equipment design for tilted conveyor belts.

- Automatic sorting of product categories in crates for slaughterhouse’s end of line and packaging stations.

- Other simultaneous inspections.

Functionalities

- Product categories classification: meat, fish or other food industryproduct references.

- Automatic classification between product and subproduct families:

- ID points automation

- Verification of registered data in ID points

- Validation of product category label content before printing

- Association of product categories with external traceability devices (RFID, barcode readers).

- Easy integration and communication with external devices using Easy Connect technology (storage of results in accessible SQL databases, OPC UA, MQTT, TCP communication protocols).

- Possibility of continuous inspection without stopping the crate, or in static mode.

- Automatic classification between product and subproduct families:

- Inspection of foreign bodies and quality anomalies.

- Inspection of production anomalies.

Automatic inspection for foreign bodies or quality deviations in fresh or bulk products on conveyor belts, with top inspection.

Functionalities

- Detection of superficial foreign bodies: plastic, gloves, hair, cardboard or any other visible foreign body in the image.

- Product quality deviations: shape anomalies, content anomalies, burnt, etc.

- Missing product: absence of product, product count, etc.

- Selective rejection.

- Automatic inspection of containers or trays from the top.

- The equipment is coupled to the existing conveyor system.

Functionalities

- Inspection of sealing/packaging anomalies:

- Entrapment of product in the weld.

- Creases or wrinkles in the film or other quality defects.

- Inspection of product characteristics or anomalies inside

the product:- Foreign bodies.

- Degraded product.

- Lack of product or incorrect presentation.

- Inspection of labelling (or printing on film) on top of the packaging:

- Verification of texts/printed fields with labeller/ERP.

- Selective rejection.

- Automatic inspection of foreign bodies in open hoppers: grinders, mixers, etc.

Functionalities

- Detection of foreign bodies: low density plastics, fragments of boxes, gloves, cardboard or any foreign body or anomaly visible in the image.

Vision technologies

High-speed vision performance

Our high-speed INSPECTRA HSP®, technology enables us to offer the fastest in- line inspection speeds on the market. Our extensive experience in the development of innovative inspection equipment for the most demanding production processes in the food industry has enabled us to develop and optimise the most advanced processing hardware and software architectures. We include parallelisation technology with an efficient distribution of processing threads with state-of-the-art hardware.

The high speeds and performance of our equipment allow us to process a huge amount of data and act in very short times with the rejection systems.

Artificial

intelligence

Our equipment can optionally incorporate artificial intelligence technology by Deep Learning for advanced inspections. We have adapted the technology and called l INSPECTRA Easy AI® Through a preliminary training phase, the processing system is able to automatically learn the type of defect being inspected, offering high inspection power and throughput.

We have accumulated extensive experience and case studies of process information in the food industry, which allows us to have the best performance in neural networks.

Centralised

architecture

For multiple inspection points, our AI Sorters offer the possibility of centralised control and monitoring, thus matching your equipment to the most efficient and effective control architecture specifically adapted to your plant. Different configurations of vision and control modules are available, we can advise you on the best configuration for your specific inspection application.

RFID technology

and code readers

For sorting applications of product categories in crates, the AI Sorter is equipment is ready to receive crates traceability data provided by external customer devices such as RFID and barcode readers.

The equipment integrates into your production line, and it is adapted to the main communication protocols in the industry.

Do you need more information?

If you would like more information about AI-Sorter equipment, please fill in your details and we will contact you to send you the technical catalogue.